Services

Custom Research and Development

We have 30 years of prototype design experience. If you have an idea, we can help bring it to life. This prototyping does get expensive, however. Anything from custom pistons to a complete engine can be built using modern CAD/CAM technology. We have all the resources necessary to build just about anything including complete “full works" aftermarket engines. It’s possible. There is no box.

Contact us for more information. This prototyping does get expensive, so serious inquires only please.

Contact us for more information. This prototyping does get expensive, so serious inquires only please.

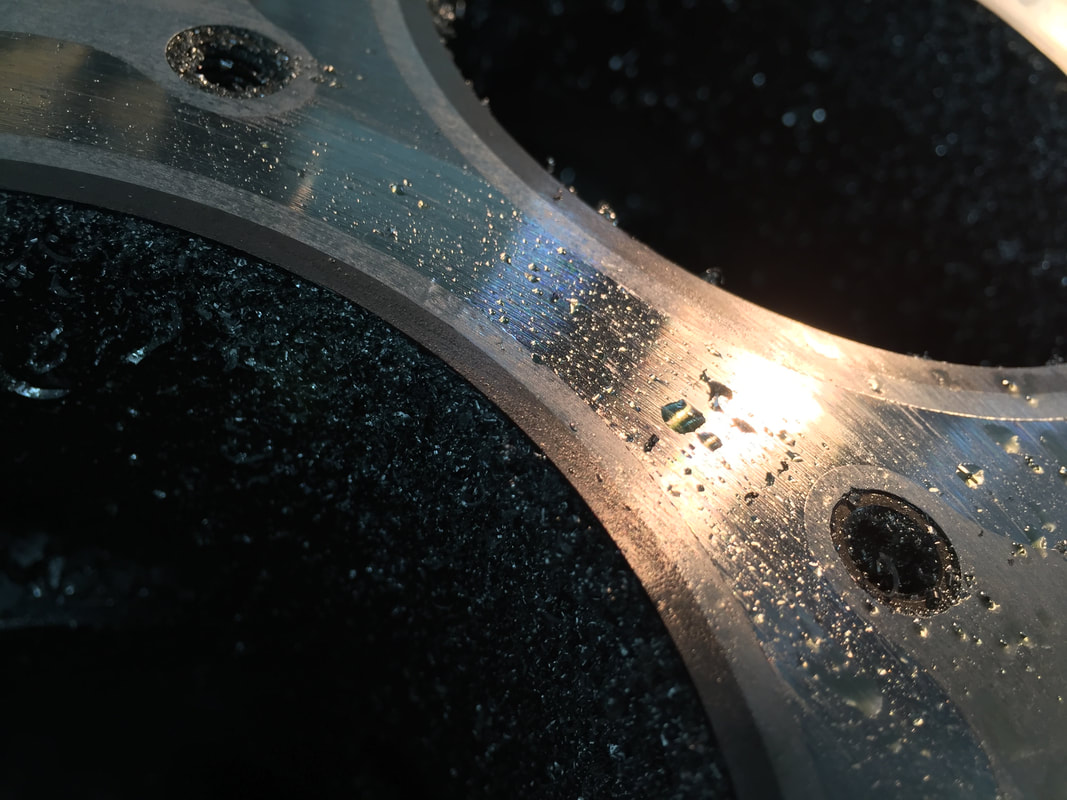

Machining

Any powerful, reliable engine build requires strong, skilled machine work. We at DBR are dedicated to this thinking.

Contact us for pricing and more information.

Contact us for pricing and more information.

Custom ECU upgrades

Porting

Cylinder porting is a true art. It involves a meticulous science and a little black magic. I could go on forever about porting. There is a lot of information in the technical section if you take the time to read it, however most of this applies to real two strokes that have expansion chambers and have the ability to achieve 100% volumetric efficiency. Most two-strokes operate with a gear box or torque converter that limits the power band to roughly a 3000 rpm window. Our tugboats have to pull hard from idle and rev to the moon. This presents the outboard engine builder with a challenge. Hats off to Mercury for their remarkable success in this art.

OMC, Johnson/Evinrude, refrigerators, anvils—whatever you want to call them— their porting isn’t quite on the same level in our opinion. However in their defense, OMC only had a target of around 225 HP, which they accomplished. Their F-1 V-8 engines were strong back in the day. These flaws provide us with an opportunity to make these engines haul ass. Porting is the key. This porting thing can make or break your build. You can have the best parts bolted onto your engine, but pair that with a bad port job, and you have one expensive slow ride. I have been there before, and I imagine some of you have as well. The great thing about these engines is their potential to be improved. If Yamaha Racing came up with a 3.3 liter engine design, I would be all over it. Huge numbers would be possible. Yamaha would probably have trouble building a gearbox that could handle the power.

At DBR, we have taken 30 years of two stroke porting experience with all types of engines and have tried to build the fastest possible outboards in the world. We haven’t tried it all yet, but I estimate we have made well over 5,000 dyno pulls developing what we race today. If we build something for you, we can promise that you will be very happy with the results no matter what the decided cubic inch and power target level. We proudly claim that we can build both ski and full-blown racing engines that have reliability second to none. Of course, proper engine management and a host of other parts are involved.

Contact us for pricing.

OMC, Johnson/Evinrude, refrigerators, anvils—whatever you want to call them— their porting isn’t quite on the same level in our opinion. However in their defense, OMC only had a target of around 225 HP, which they accomplished. Their F-1 V-8 engines were strong back in the day. These flaws provide us with an opportunity to make these engines haul ass. Porting is the key. This porting thing can make or break your build. You can have the best parts bolted onto your engine, but pair that with a bad port job, and you have one expensive slow ride. I have been there before, and I imagine some of you have as well. The great thing about these engines is their potential to be improved. If Yamaha Racing came up with a 3.3 liter engine design, I would be all over it. Huge numbers would be possible. Yamaha would probably have trouble building a gearbox that could handle the power.

At DBR, we have taken 30 years of two stroke porting experience with all types of engines and have tried to build the fastest possible outboards in the world. We haven’t tried it all yet, but I estimate we have made well over 5,000 dyno pulls developing what we race today. If we build something for you, we can promise that you will be very happy with the results no matter what the decided cubic inch and power target level. We proudly claim that we can build both ski and full-blown racing engines that have reliability second to none. Of course, proper engine management and a host of other parts are involved.

Contact us for pricing.

Dyno Testing and Tuning

DBR is now offering dyno tuning to the public. It is very satisfying to make positive results as well as humbling to see some negative results. You can move forwards just as easy as it is to move backwards. The secret to reliable performance is dyno testing and tuning along with ECU mapping. See how hot your “hot rod” really is. We can help you map and optimize your engine or even help you quantify the latest part you bought or built. If you spent thousands of dollars and countless hours building an engine, it literally can go to waste without proper dyno tuning. We can and will adapt to almost any outboard. Dyno testing will be on a limited basis as we are constantly developing our own products. Crate up your complete engine and we are more than willing to help.

Pricing is based on a daily rate of $800/day @10 hr days. Set up and wrenching days are $500/day. Contact us for more information or for specific inquiries.

Pricing is based on a daily rate of $800/day @10 hr days. Set up and wrenching days are $500/day. Contact us for more information or for specific inquiries.